The factory is nearing completion of the new ITZ M2 Base mold. This is a mold Mark has been working on since the Starter Bases were released.

What is the M2 Base and how will it benefit the game?

The design improves the performance of all ITZ Bases by using Pre-Shaped Prongs. This takes a lot of the guesswork and frustration away from the coaches learning to tweak at a higher level. Instead of the prongs molded to the shell (which necessitates them being straight), all the prongs are mounted to front and back dials (similar to the Starters). This allows us to Pre-Shape the prongs for better out of the bag performance as well as saving valuable time and frustration tweaking.

Are these going to win tournaments out of the bag?

Hell NO but, in the hands of skilled tweakers they will have a place on championship teams.

Are they approved for tournament play?

We submitted the drawings of the M2 Bases to the TOC and received approval before the factory started on the molds so they will be legal for tournament play.

Why did we design a new base?

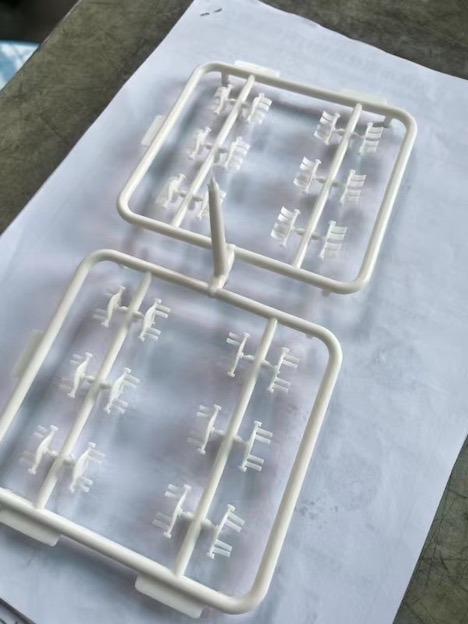

This was an extremely expensive project requiring two injection molds; one for the prongs and one for the shells. We believe in electric football and we see a major growth coming to the hobby with Bryan and Anne bringing their passion and experience to Tudor Games, we want to be sure new coaches can experience the full potential electric football can bring. Invisibases caused people to laugh at the game again and quit. we want to help change that perspective!

What does it take to design a new base for electric football?

This process takes a long time and a lot of foresight. The concept comes first and that is hours of brainstorming and questioning every single detail of the project. Every millimeter must be checked and double checked. We usually spend several months planning the design.

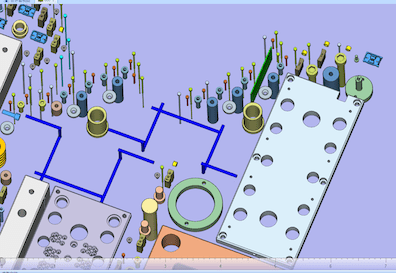

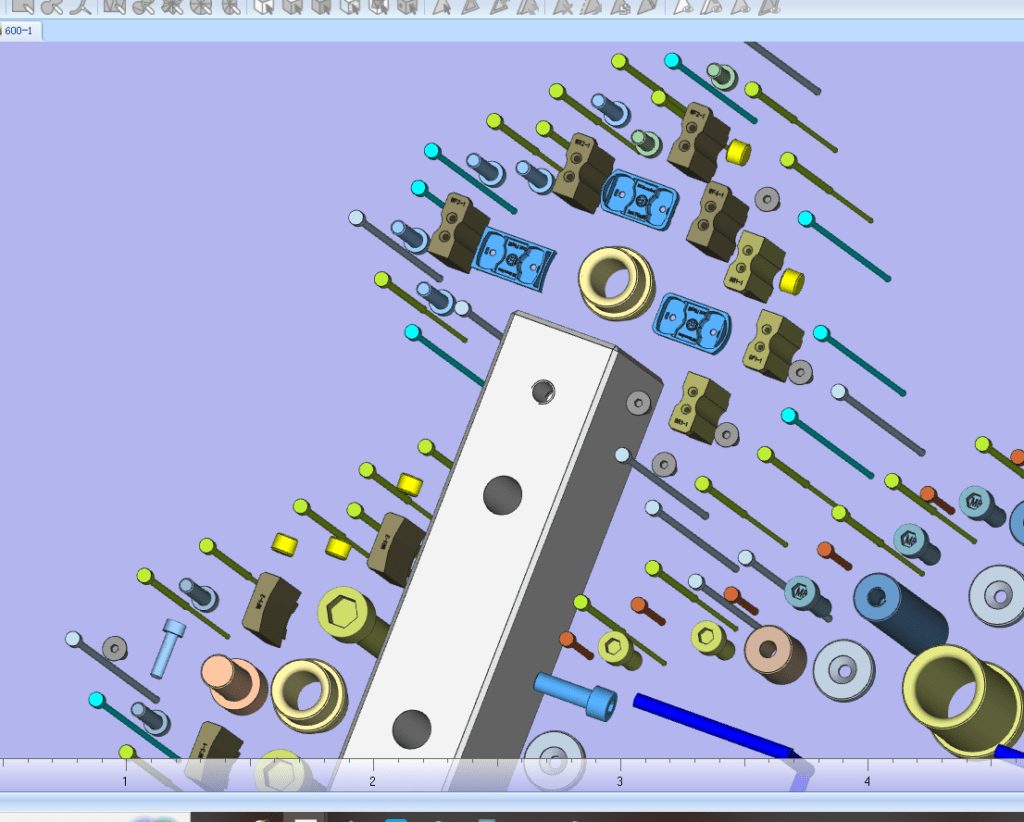

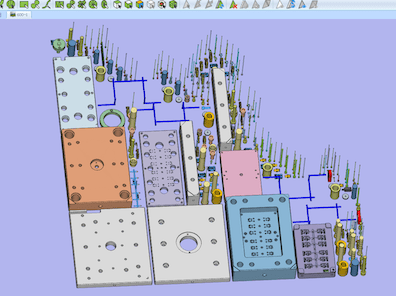

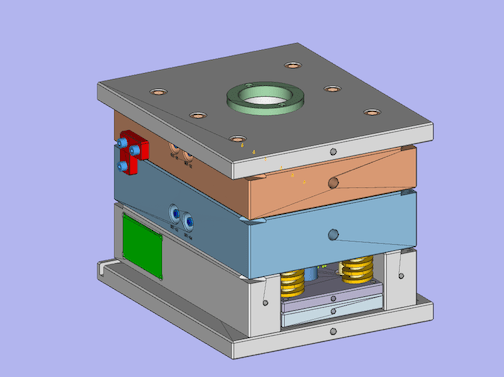

Once we have the concept down, Mark starts designing the bases in CAD software. During this long process more questions and ideas come up which leads to a refinement of the concept. He usually spends several months on the design work. At this point, we have a final conference to see if we have missed anything and question everything about the base. Once it goes in steel, there is no turning back.

We then contact the Factory and submit the CAD drawings. They will have meetings with their engineers and submit any questions or issues in building the mold. It is at that point they submit an invoice. The cost of the tooling is extremely expensive as we use a high-end company.

We included CAD images of the molds so you can appreciate all the moving parts that have to be designed to make top flight bases.

We hope you now have a better understanding of what we do to bring you the best in electric football.